PlantPAx ModelBuilder Enable Real-time Monitoring and Process Prediction

http://www.kblhh.cn 2012-01-20 17:05 來源:羅克韋爾自動化(中國)有限公司

Benefi ts

Improves Product Quality

• Minute-by-minute feedback enhances operators’ decisions in real time to meet changing process

and manufacturing conditions

• Predictive measurement of key product quality characteristics reduces variability

• Soft Sensors can be easily integrated with control systems to provide tighter process performance

Reduces Production Costs

• Decreases off -spec production and raw material waste by identifying process errors before they occur

• Reduces lab sampling costs by lengthening the frequency between samples and eliminating unnecessary tests

• Simulates future outcomes and potential cost and risk of options through sophisticated “What-Ifs”capability

Overview

Leading in today’s competitive manufacturing environment requires maximizing the performance of every process throughout the plant.But you can’t control what you can’t measure and timely, accurate process measurements aren’t always available. Now there’s a cost-eff ective way to augment your laboratory analyses and instrumentation – with PlantPAx ModelBuilder. ModelBuilder enables real-time monitoring and prediction of the process characteristics critical to peak performance. The result is improved production effi ciency, reduced product variability and waste,and increased profi tability.

Soft Sensors Overview

A Soft Sensor is a model that predicts process values based on real-time process data. Soft sensors provide virtual measurements of variables that are diffi cult to measure by physical devices due to the limited reliability and associated cost. This model supplements traditional laboratory measurements by reducing the time interval needed to supply results from hours to minutes.

The Challenge

Many production processes are under-instrumented. Whether it’s due to insuffi cient lab capacity or the expense of the testing, many production processes require hours or even days to produce lab samples. During this time,the production process may have unknowingly drifted out of specifi cation.

The Solution

PlantPAx ModelBuilder creates online predictive models that augment hardware instruments and laboratory analyses to provide real-time estimates of process and product conditions. These software models, in the form of a Soft Sensor, provide the feedback and predictive process

information needed to keep production on track.

Building Soft Sensors

PlantPAx ModelBuilder can be used “off -line” to better understand process behavior. In off -line mode, you can analyze complex linear and nonlinear processes.Using the historical process data, the analysis tools can extract, clean and model historical process data to gain insight into the key process variables that most aff ect quality.

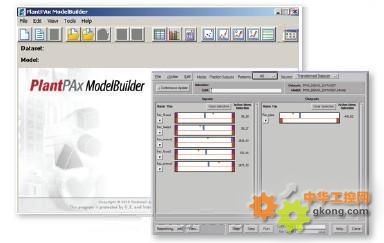

Simple and Intuitive User Interface

ModelBuilder makes model development easier through the use of point-and-click technology. This environment automates and guides the user through data extraction,modeling and scenario building, performing tasks in minutes that used to take hours or days. This environment allows a greater ease of use while incorporating best engineering practices.

Extract Data from Any Environment

ModelBuilder uses data extraction to pull data from historians and immediately make the data available for modeling into an easy, spreadsheet-like format.

Data Pre-processing tools

Data pre-processing is a critical part of creating a robust model of your process. With the pre-processing data tools you can analyze tens of millions of data points in minutes.

• Easily edit and remove data

• Combine multiple fi les for analysis

• Merge variables with diff erent dates and times

into a common dataset

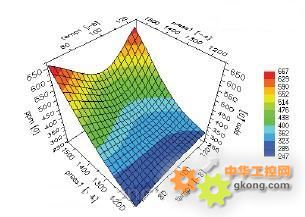

Enhanced Data Visualization

ModelBuilder’s advanced data visualization features allow you to easily see patterns in your data. The tool provides an extensive set of plotting options for use in screening and analyzing data, including histograms,principle components, time series, correlation, scatter and probability. Three-dimensional plots of the modeled outputs allow users to examine the response surface,depicting the multidimensional impact of process variables.

Automated Model Building and Training Model Analysis RSLogix Deployment Typical Applications Additionally users can plot process model data in a variety of formats: Correlation Plot, Time Series Plot, Histogram Plot, XY Plot and Principle Components Analysis (PCA) plot.

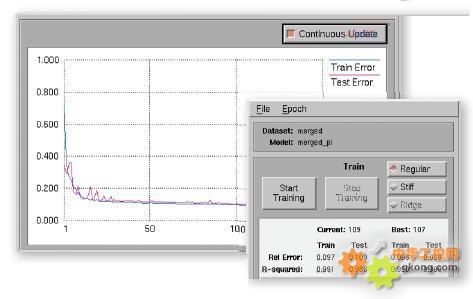

Modeling the process is performed in two steps:confi guring a model, and training the model. Users

confi gure a model by specifying which variables are inputs and which are outputs of the process, and specify time delay relationships that exist between the variables.ModelBuilder has the option to

PlantPAx ModelBuilder provides a wide range of model analysis tools to validate model quality. End users can simulate complex and diffi cult process using the Analysis plots and What-If scenario tool. The confi gured model can be used to examine the infl uence of the input variables on the output variable.

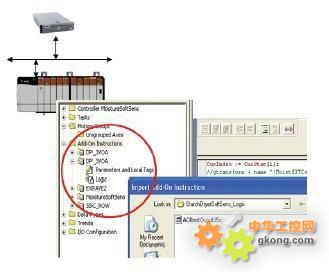

Optional On-Line Applications

An optional component, SoftSensor Designer, is available with PlantPAx ModelBuilder to convert models to Add-On Instructions (AOI). End users create online predictive models to provide real-time estimates of the process. These software models, in the form of a Soft Sensor®, provide the feedback

and information to keep the online procesprocess.

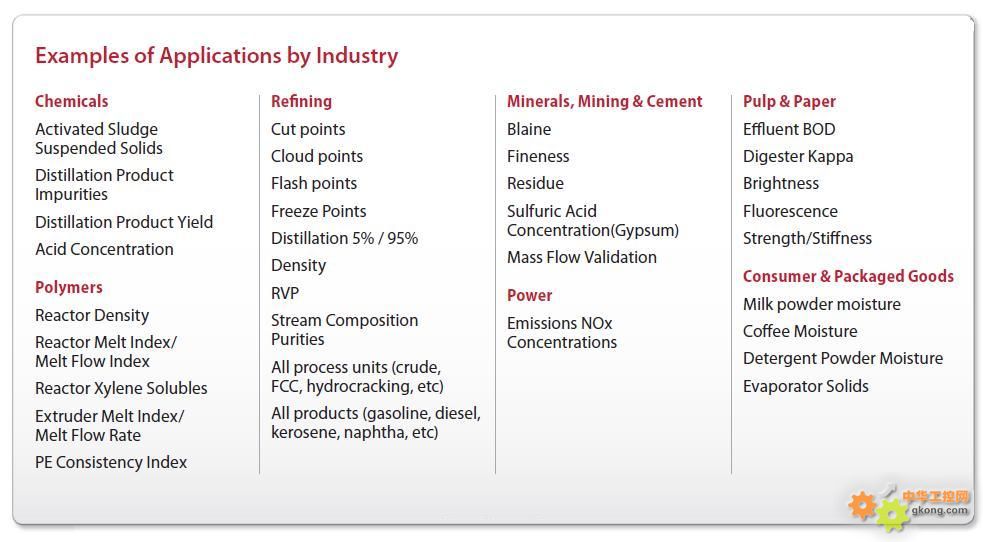

PlantPAx ModelBuilder is primarily a data mining tool designed for continuous processes industries with highly variable product quality that are diffi cult to measure and that can’t be measured directly online. This includes processes that continuously operate against a single constraint, continuously produce the same product with the same feed at the same production rate.

ModelBuilder’s “What-If” functionality provides an interactive interface to simulate model inputs and observe the magnitude of their impact on the predicted outputs. These simulations are useful for understanding the model behavior and the performance given diff erent sets of inputs.compute time delay automatically.

The auto modeler wizard simplifi es model building by defaulting many of the optional confi guration and training parameters. It can build prediction models using an intuitive user interface providing simple usage for infrequent modelers. Advanced users can specify all parameters to get even more accurate models.

Model Training is the process of testing and adjusting model parameters to fi nd the best available model. When users train a model, the model uses historical data to simulate the actual process. Additionally with the available visualization end users can control and monitor performance of the training process or change parameters during the process by pausing and restarting the training.

相關新聞

- ? 羅克韋爾自動化ThingWorx® “一瓶一碼”賦能儲氫瓶全鏈追溯

- ? 羅克韋爾自動化推出彈性 MES 產品組合,在基于云的彈性平臺上實現 IT/OT 融合

- ? 羅克韋爾自動化與冠英科技集團聯合發布集群共享智造出海方案

- ? 羅克韋爾自動化與達實智能簽署戰略合作協議,共拓數智零碳未來

- ? 羅克韋爾自動化推出新型 Micro820 L20E 控制器

- ? 羅克韋爾自動化:自動化需求推動第四季度利潤與營收超預期

- ? 羅克韋爾自動化亮相第八屆進博會,四大關鍵詞助推新質生產力發展

- ? 羅克韋爾自動化即將亮相第八屆進博會,共創智能零碳新未來

- ? 羅克韋爾自動化報告強調人工智能、物聯網和網絡安全是數字化轉型的關鍵驅動力

- ? 羅克韋爾自動化助力開拓儲能行業創新藍海